Background Application:

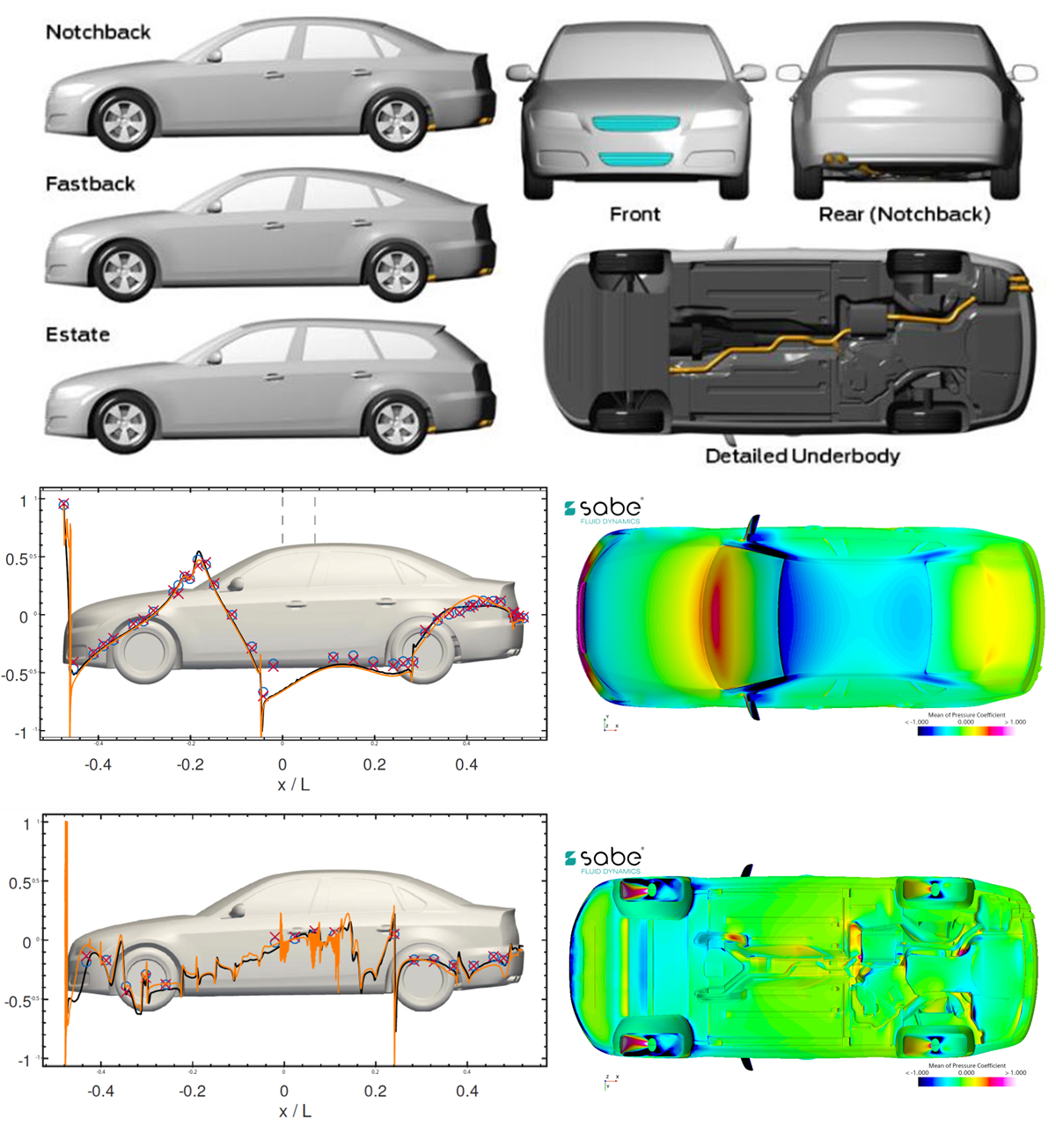

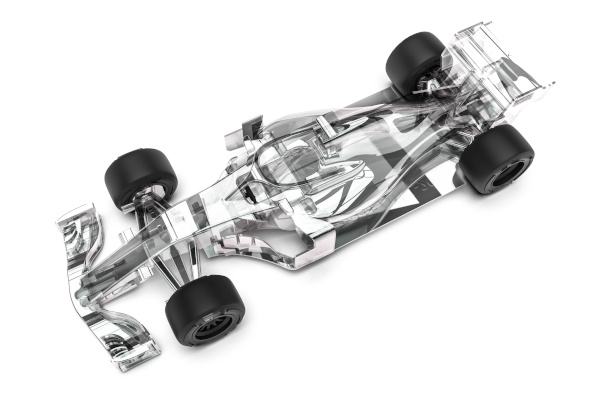

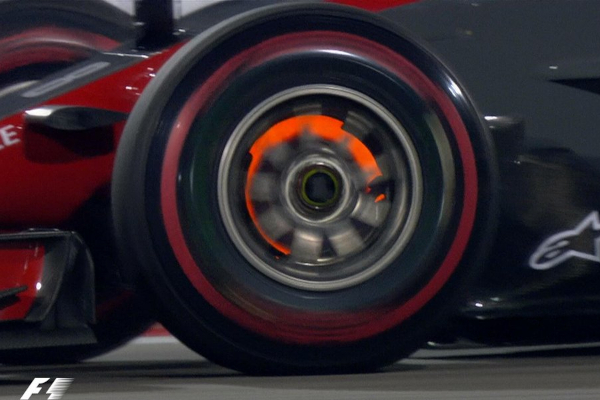

Aerodynamic development and performance/correlation analysis of road and racing cars.

Engineering Challenge:

Judging how to deploy different development tools and methods in complementary manner, making best of use of the strengths of each approach.

Understanding the real-life application performance, including the uncertainty around the data used as reference for correlation.

Our Experience:

Sabe Fluid Dynamics has many years of experience working on most aspects of the aerodynamic development, covering design, CFD simulations, wind tunnel and track testing, aerodynamic performance and correlation analysis. Our experience shows that the complementary use of the information from multiple domains is by far the most effective way of developing a design which is high performing throughout a wide range of “real world” operating conditions.

The aerodynamic development of road and racing cars is typically carried out through a combination of computational simulations, experimental tests in wind tunnels and road/track testing of the actual vehicle or a full-scale prototype. Each of these development domains offer advantages and challenges, with the best results often achieved by the complimentary use of the three.

Road or track testing offers the correct geometrical representation, a realistic environment and can offer a good representation of the expected operating conditions, although the range of conditions has to be, sometimes, narrowed down due to practicalities around the testing repeatability and measurements systems in place.

The challenges of full-scale testing are the high cost for building a highly specialised prototype, the lack of control of the environment which can introduce significant noise and compromise the repeatability of the test, and the difficulty in decoupling the variables affecting the relevant measurements.

Wind tunnels offer a controlled environment where suitable repeatability levels can be achieved for the comparison between different designs and it allows for the decoupling of the effect of variables such as ride height, yaw, pitch, roll and steer on the loading.

Wind tunnels offer a controlled environment where suitable repeatability levels can be achieved for the comparison between different designs and it allows for the decoupling of the effect of variables such as ride height, yaw, pitch, roll and steer on the loading.

The downsides of such tests are the high cost and the requirement, in many instances, for smaller scale models which can create differences to the real application such as compromises for the packaging of the motion and measurement systems, operating Reynolds number and distinct structural properties of the parts, which in turn often result in divergence of deformed shapes compared to reality once the wind and pre-load forces are established.

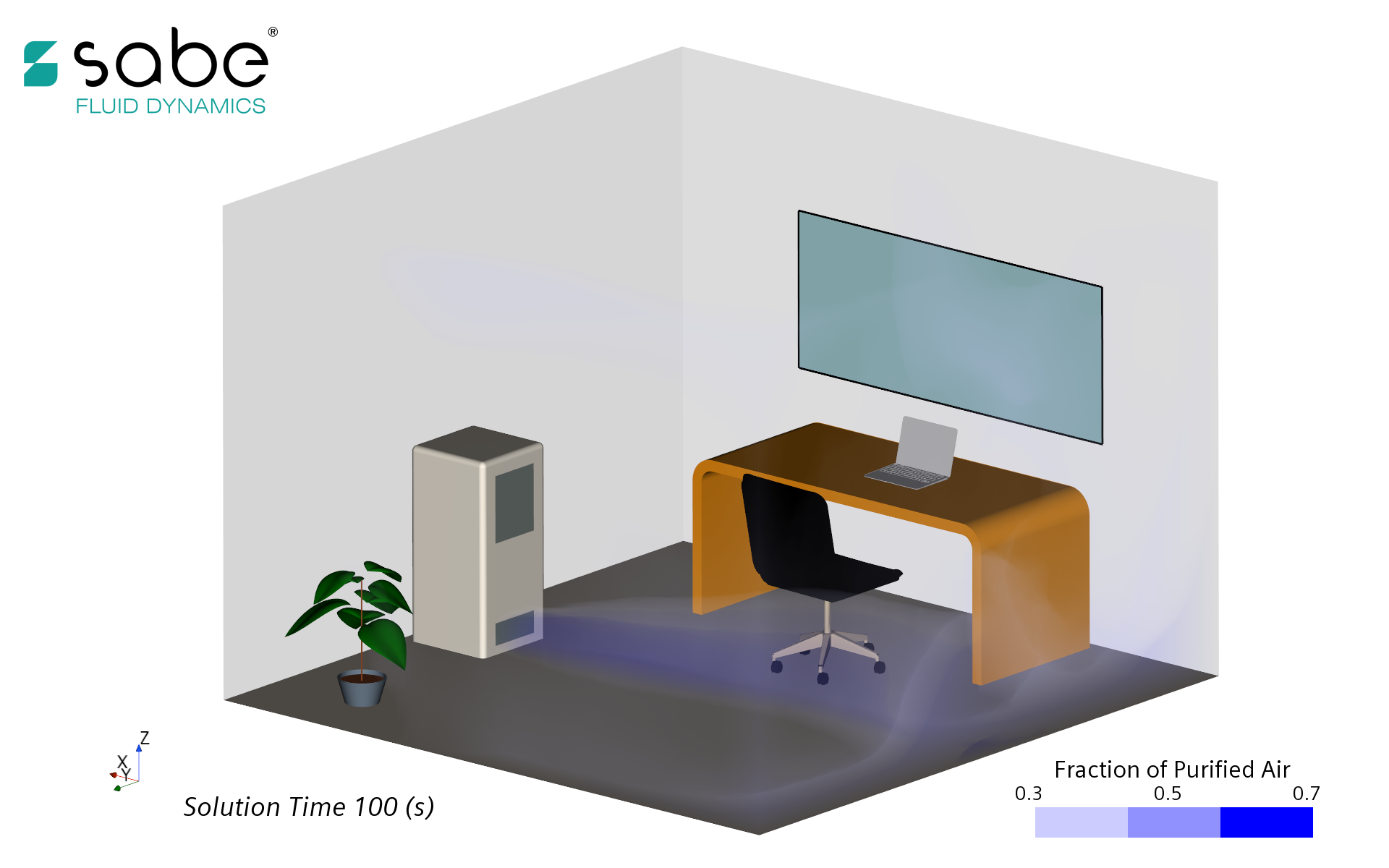

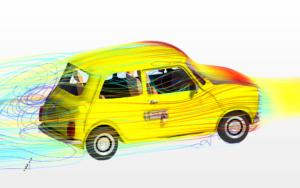

Computational fluid dynamics offer benefits such as the relatively lower cost given the non-requirement for a physical model or prototype, a controlled environment for the performance evaluation between designs, as well as the ability to evaluate the performance in real-world operating conditions, including the effect of flow curvature during cornering, side wind, aeroelasticity, thermal effects and others.

The limitations of CFD are well advertised and mostly relate to simplifications regarding turbulence modelling, although nowadays most commercial CFD codes have a very large number of turbulence models available, covering a wide range of modelling complexity levels.

Sabe Fluid Dynamics has many years of experience working on most aspects of the aerodynamic development, covering design, CFD simulations, wind tunnel and track testing, aerodynamic performance and correlation analysis. Our experience shows that the complementary use of the information from multiple domains is by far the most effective way of developing a design which is high performing throughout a wide range of real-world operating conditions.

Our experience also shows that CFD can be an incredibly powerful tool not only for design development, but also for exploring sensitivities and understanding the critical areas affecting correlation. Both while working in Formula 1 and through the development of consultancy projects for automotive companies, we worked on solving problems regarding poor correlation levels across the domains. We found many instances in which improving the quality of the modelling of the geometrical and operating conditions aspects returned the largest improvements in the correlation levels, often without any need to further increase the level of complexity of the CFD model.

Our experience also shows that CFD can be an incredibly powerful tool not only for design development, but also for exploring sensitivities and understanding the critical areas affecting correlation. Both while working in Formula 1 and through the development of consultancy projects for automotive companies, we worked on solving problems regarding poor correlation levels across the domains. We found many instances in which improving the quality of the modelling of the geometrical and operating conditions aspects returned the largest improvements in the correlation levels, often without any need to further increase the level of complexity of the CFD model.

We ultimately work with our clients towards a process which is fit for purpose, avoiding overcomplex and overly expensive solutions both in terms of resources requirement and turnaround time. We also consider our clients’ long-term ambitions and work with them advising on the steps required to further improve their processes.

Contact Sabe Fluid Dynamics to discuss your challenge!

Sabe Technology Ltd | +44 (0) 1327 221427 | [email protected]