Background Application:

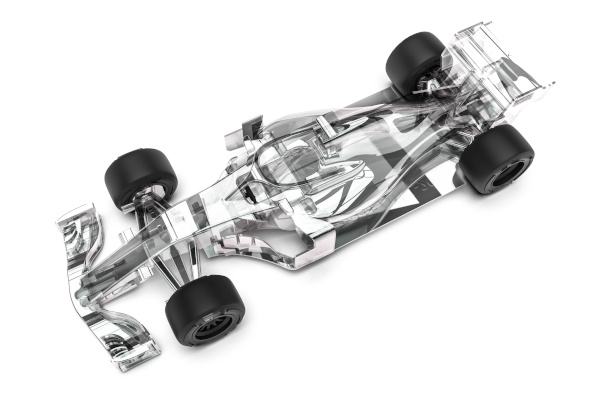

Development of a fully automated CFD process for aerodynamic development.

Engineering Challenge:

Automatically processing highly complex input geometries, locally repairing critical areas while maintaining adequate surface representation an obtaining consistent and repeatable solutions.

Outcome:

A fully automated process was developed, taking the CAD input geometry and returning the results & post-processing without any intermediate user intervention.

Our Experience:

Sabe Fluid Dynamics has many years of experience working on most aspects of the aerodynamic development, including the development of data infrastructure and process automation.

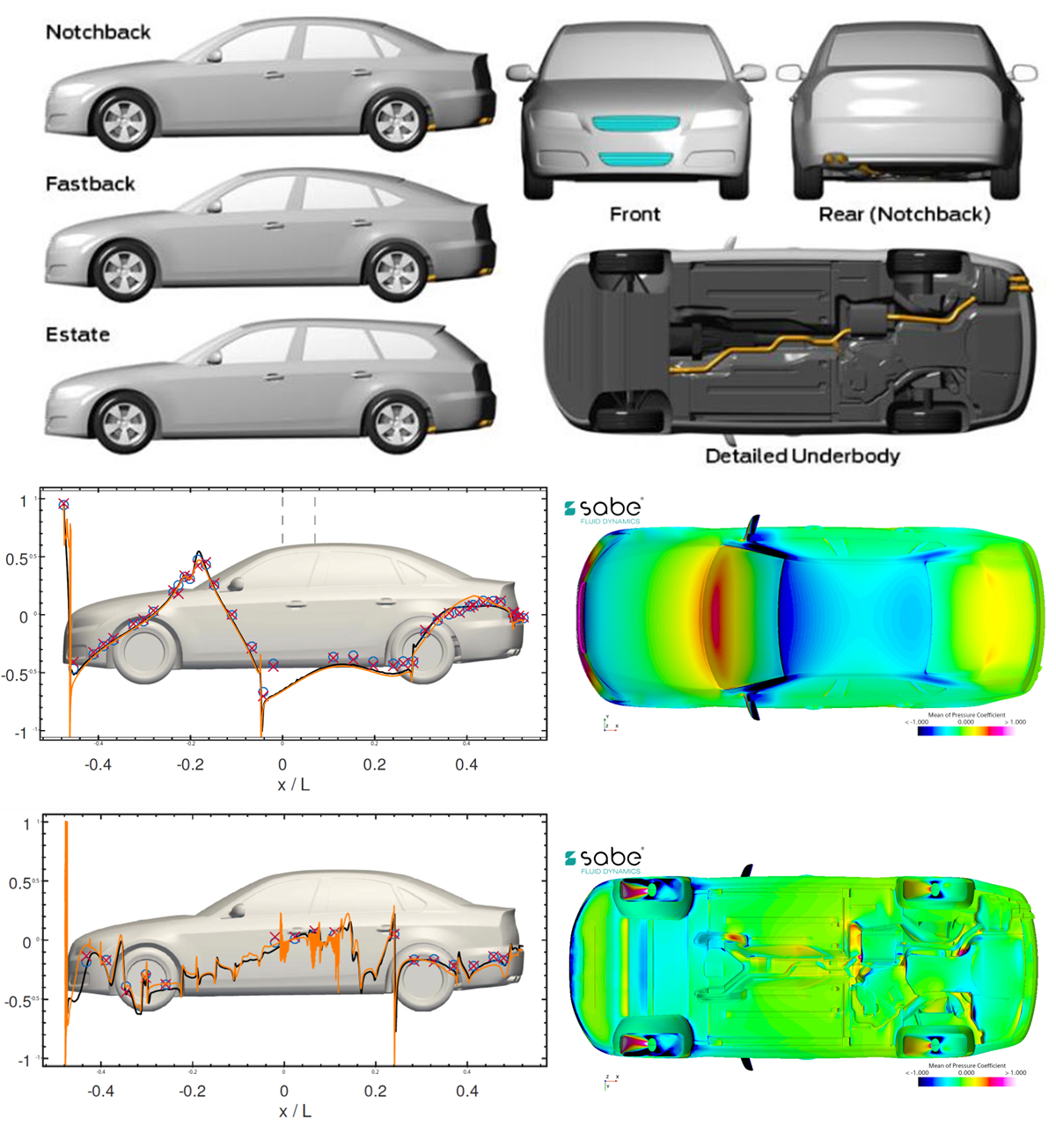

Sabe Fluid Dynamics developed a project for a design and aerodynamics consultancy company with vast experience supporting motorsport programs for many companies.

Over the years they have been using different external consultants to develop their CFD simulations for the aerodynamic programs, however the high demand for their services ultimately justified the decision to build their in-house CFD expertise to take full control of future developments.

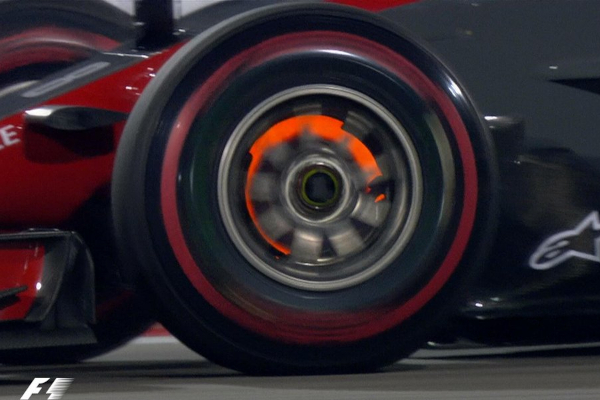

Sabe Fluid Dynamics was tasked with the job of developing a fully automated CFD process, taking the CAD input and returning the results without any intermediate user intervention. The engineering challenge in this project was developing a routine which could robustly process highly complex input geometries, locally repairing critical areas while maintaining adequate surface representation, and obtaining consistent and repeatable solutions throughout the development program.

The process was developed around the software STAR-CCM+, with a large quantity of Java classes and methods developed to control the process. Information regarding geometrical topology and key setup parameters are provided to the process through an input file, which can be quickly created through a UI specifically developed. The process is able to run straight-line or cornering cases, with or without thermal input.

The process was benchmarked against a reference project and approved to be deployed. Sabe supported the client during its first aerodynamic development project with the newly developed process, in which over 200 simulations were successfully carried out.

During this period, the client acquired hardware and hired a CFD aerodynamicist, now being able to develop their CFD simulations in-house.

Sabe Fluid Dynamics is able to support our clients with the development of data infrastructure and process automation, contact us to discuss your challenge!

Sabe Technology Ltd | +44 (0) 1327 221427 | [email protected]